-

Acrotec Medtech

65 Richard Rd

Warminster, PA

18974

United States - 40,000 sq. ft., 1

- 267-961-2600

- 50+ employees

- Founded in 2014

- Operating in North America

- Visit Website

CEO

Certificates

ISO 13485

FDA Registered

Changes saved

- Component Parts

- Instruments

- Manufacturing

- Materials/Bio and Performance

- Materials/Metals

- Surface Preparation/Treatments

Made For Life

About Us

Acrotec Medtech is a highly motivated team with one goal: to be the industry-leading medical device manufacturer. Our Medtech division was designed and custom built for the specific needs of the medical device industry. We specialize in production of the most complex implants on the market for joint replacement, spine, sports medicine, and trauma.

Our Capabilities

5-Axis Milling

- 8-axis machine with 7-axis live profile milling

- High speed 5-axis mills allow single-operation machining

- Surface milling of extremely complex geometries

- Tool management and tool breakage detection allow uninterrupted processing

- Tool speeds in excess of 40,000 RPM

5-Axis Milling

- 8-axis machine with 7-axis live profile milling

- High speed 5-axis mills allow single-operation machining

- Surface milling of extremely complex geometries

- Tool management and tool breakage detection allow uninterrupted processing

- Tool speeds in excess of 40,000 RPM

Swiss Turning

- Multi-axis control allows for complex manufacturing

- In-line gun drilling for cannulated products

- Multiple operations can be accomplished simultaneously

- Tool speeds in excess of 80,000 RPM

- High tolerance capabilities of +/- .0001

Swiss Turning

- Multi-axis control allows for complex manufacturing

- In-line gun drilling for cannulated products

- Multiple operations can be accomplished simultaneously

- Tool speeds in excess of 80,000 RPM

- High tolerance capabilities of +/- .0001

Wire EDM

- FANUC Wire EDMs capable of 72-hours of unmanned production

- Accuracy capable of +/- 3.0 μm

- iPulse2 keeps discharge gap constant for highly precise corner accuracy

- Custom made Fixtures and tooling design and produced in-house specific to your implants

Wire EDM

- FANUC Wire EDMs capable of 72-hours of unmanned production

- Accuracy capable of +/- 3.0 μm

- iPulse2 keeps discharge gap constant for highly precise corner accuracy

- Custom made Fixtures and tooling design and produced in-house specific to your implants

PEEK Machining

- Variety of equipment dedicated to PEEK manufacturing

- Computer generated analysis optimizes “part-per-bar” yields

- Dedicated PEEK specialists employ the latest deburring methods

- Ability to eliminate Human Contact on PEEK implants

- Fully validated PEEK cleaning process

PEEK Machining

- Variety of equipment dedicated to PEEK manufacturing

- Computer generated analysis optimizes “part-per-bar” yields

- Dedicated PEEK specialists employ the latest deburring methods

- Ability to eliminate Human Contact on PEEK implants

- Fully validated PEEK cleaning process

Quality

- ISO 13485:2016 certified

- FDA registered

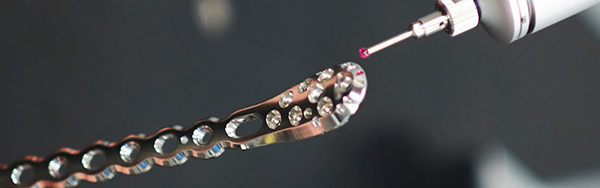

- Optical/video inspection capabilities

- Full process validations and control plans

Quality

- ISO 13485:2016 certified

- FDA registered

- Optical/video inspection capabilities

- Full process validations and control plans

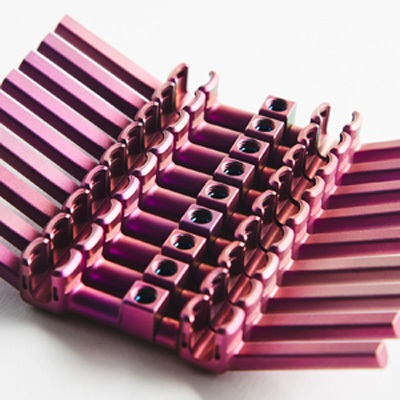

Assembly & Finishing

- Type 2 and 3 titanium anodizing

- Electro-polishing

- Laser marking

- Nitric and citric passivation

- Ultrasonic DI clean and rinse

- Dedicated and environmentally controlled assembly areas

Assembly & Finishing

- Type 2 and 3 titanium anodizing

- Electro-polishing

- Laser marking

- Nitric and citric passivation

- Ultrasonic DI clean and rinse

- Dedicated and environmentally controlled assembly areas

Gallery

Facilities

65 Richard Rd

Warminster, PA

United States

Warminster, PA

United States

267-961-2600